The Toughest Coating on the Market

There are several aspects to think about when choosing a coating for steel roofing in Ontario.

- What’s Underneath

- Flexibility

- Durability

- Reliable Fasteners

What’s Underneath – Why is it important?

Galvanizing is important in metal roofing because it provides essential protection against corrosion, significantly extending the lifespan of the roof. Here’s why our G90 galvanizing is critical:

- Corrosion Resistance:

Metal roofing materials, such as steel, are prone to rust and corrosion when exposed to moisture, oxygen, and environmental pollutants. The galvanizing process coats the metal with a layer of zinc, which acts as a barrier to prevent these elements from coming into contact with the steel. - Sacrificial Protection:

Even if the galvanized coating is scratched or damaged, zinc provides sacrificial protection. This means that the zinc corrodes preferentially to the steel, preventing the underlying metal from rusting. - Increased Longevity:

Galvanized metal roofs last longer because the zinc coating slows down the deterioration process. This durability makes galvanized roofing a cost-effective choice over time. - Low Maintenance:

Galvanized roofing requires less maintenance compared to non-galvanized steel, as the protective zinc layer minimizes the need for frequent repairs or repainting due to rust. - Environmental Benefits:

Galvanized metal roofing is recyclable, and its durability means fewer resources are consumed in replacements over time, making it a more sustainable option.

Galvanizing is essential for metal roofing because it enhances durability, reduces maintenance costs, and provides long-term protection against the elements, ensuring the roof performs effectively for years.

Our steel is sourced locally from Hamilton, Ontario. Coming from ArcelorMittal Dofasco where the steel is made and galvanized. From Dofasco it travels to Baycoat, also in Hamilton. Baycoat applies the coating. Each coil that is coated there goes through intense testing to ensure it meets high quality standards.

Flexibility and Durability

Our coating is 4 mils thick, durable and flexible. Most competing coatings are only 1 mil thick. The durability of the PVC coating allows us to work with the material without worrying about scratching or cracking it. It is the only coating within Ontario that undergoes a 180 degree bend test. This test takes finished materials and folds them together. Our coating will not chip, crack or peel under this pressure. Why is this important? When your roof is being manufactured the steel is formed into the shakes and all of the trim, without compromising the coating. When it is installed, it is cut and bent to customize your roof, again without worrying about compromising the coating. LASTLY, but definitely not least, your roof will expand and contract in temperature changes constantly. Our coating will move with your roof, in even the biggest temperature swings. The PVC coating is the only coating that goes through a 30 minute boil test as well. This is to ensure that even in the most intense heat, your coating is staying put!

Reliable Fasteners for Long-Lasting Protection

We use smooth shank hot-dip galvanized nails to secure our steel shakes. These nails match the galvanized steel, preventing corrosion, aligning lifespans, and maintaining structural strength for years to come.

7 Smart Steel & Metal Roofing Colours

Black

Black Canner’s Brown

Canner’s Brown Charcoal Grey

Charcoal Grey Dark Brown

Dark Brown Slate Grey

Slate Grey Hunter Green

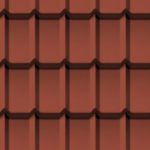

Hunter Green Tile Red

Tile Red

PVC – Toughest Coating on the Market

Hy-Grade’s PVC-based plastisol coatings provide unparalleled protection from UV rays and unbeatable resistance to scratching, fading, chalking, peeling, and cracking. Our 26-gauge galvanized steel shakes come in seven exquisite colours, ensuring your roof looks perfect for decades, giving you the peace of mind that comes with a worry-free, permanent steel roofing system.

Trust in Our Experience

Hy-Grade has been a trusted name in the industry since 1988, and we’ve learned invaluable lessons through trial and error, so you don’t have to. Today, we proudly use a PVC-based coating to offer the best in longevity, aesthetics, and value.

Don’t take chances when it comes to your roof – book your free, no-obligation consultation and quote with your local Roofing Consultant to discover why a Hy-Grade Steel Roof is Your 1st Choice for Your LAST Roof!